The Chickens are out! Equipped with 1 m broiler cage、 distributed control system、 ventilation system、feeding system、manure cleaning system、 plant management platform and other equipment of Shandong weifang shuya broiler breeding 7 factory, the first batch of chickens have been successfully released after 42 days of rearing.

There are 24 chicken houses in the whole project. 95.8*17.2 m broiler house is equipped with 4 layers and 8 columns of single side broiler cages, and 55,200 broilers are kept in a single house.

The 1m single side broiler cage adopts the intermediate brooding mode, and the second and third layers are equipped with shaped feeding nets.

One-piece injection-molded laying mesh is flat and tough enough to protect chicken claws.

Equipped with seeding feeder and screeder, feeding is more even; the residual feed in the trough is collected during the running of the vehicle, which does not affect the uniformity of the feed.

Adopting double-layer butt-spotting lamps lighting, equipped with dimming controller, managing the feeding of chickens of different ages, can accurately control the lighting brightness of the poultry house.

Equipped with EI-50 metal shutter fan, air inlet and small ventilation window produced by EI Farming, the chicken house ventilation system ensures fresh air in the house.

Fully automatic feeding system ensures that every chicken gets enough feed.

The manure cleaning system adopts automatic manure cleaning equipment, which can clean up the manure 6 times a day, preventing the accumulation of manure and ensuring the environment of the chicken coop is neat and clean.

Equipped with a distributed control system consisting of EI-DCS climate controller, small window opening controller, front-end cabinet and back-end cabinet, it carries out automated control of temperature, humidity, ventilation, lighting, disinfection, etc. in the chicken house to realize the intelligent management of the chicken farm. The controllers of the system are connected by a single line, and the wiring is simple. Operation and maintenance safety, redundancy safety and system awareness are the key considerations for Shuya to choose EI-DCS climate controller.

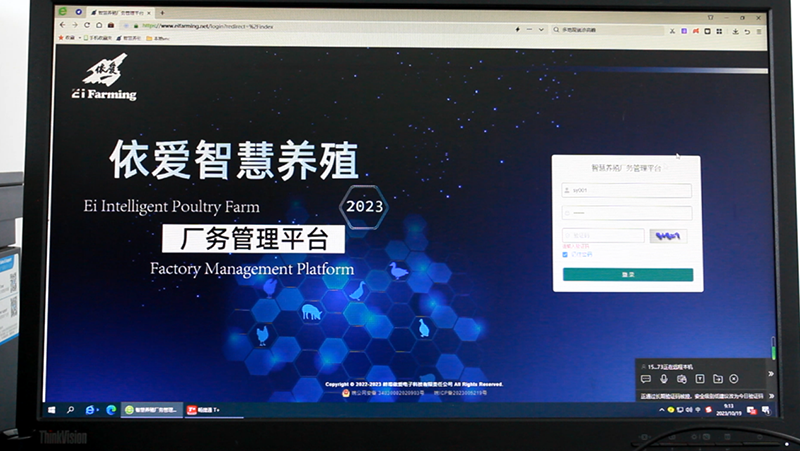

Equipped with breeding plant management platform, it can monitor the production situation of chicken farms in real time, realize data visualization and mobile management, provide scientific basis for the management of chicken farms, enhance the intelligent management of chicken farms, and realize healthy growth of chickens, efficient breeding and cost reduction.

Quality inspectors into the project site, in accordance with the “Farming Project Inspection Specification”, check the cage equipment, and fans, air inlets, ventilation windows, feed towers, controllers, and other ancillary equipment dimensions, parameters and wiring strength to meet the standard, standing in the customer’s point of view to examine the quality of the project, so that the customer can rest assured.

Shandong weifang shuya broiler breeding Co., Ltd. has been the partner of EI Farming for many years, and both sides have good cooperation in the field of incubation equipment and breeding equipment. All the chicks of Shandong weifang Shuya broiler breeding company are provided by Shandong Shuya Poultry Co., Ltd., which has an annual hatching capacity of 150 million chicks. The annual output of white-feathered broilers is 8.6 million after reaching production.

The first batch of chickens from Shuya broiler breeding 7 factory were slaughtered in 42 days on average, with average weight ≥3.2kg, survival rate >98.5%, feed-to-meat ratio ≤1.39, and EPI 535. The overall result exceeded customer’s expectation and Shuya was satisfied with the result.